Hemp Plastic: Renewable, Biodegradable, Eco-Friendly.

The world is facing a severe environmental crisis, and plastic pollution is one of the significant concerns. The extensive use of traditional plastics has led to a situation where plastic waste is choking our oceans and harming marine life. However, there is a sustainable alternative that is gaining popularity – hemp plastic. Hemp plastic is renewable, biodegradable, eco-friendly, and has numerous advantages over traditional plastics. This article explores the properties, advantages, manufacturing process, applications, and environmental impact of hemp plastic.

What is Hemp Plastic?

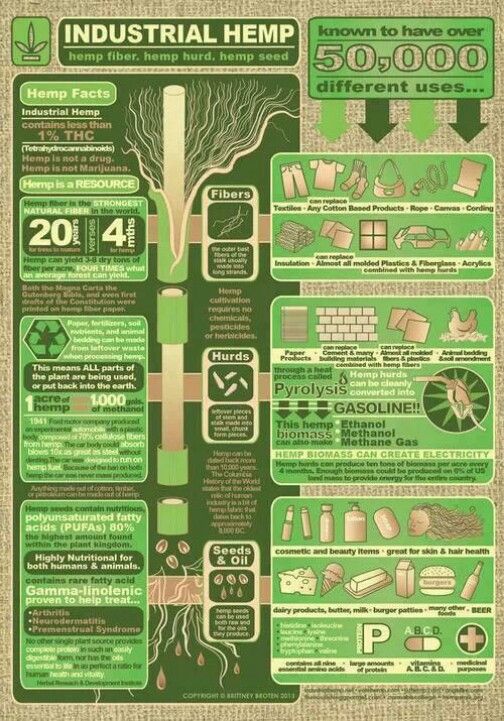

Hemp plastic is a biodegradable alternative to traditional petroleum-based plastics made from the stalks of the hemp plant. The hemp plant has been used for industrial purposes for thousands of years and has been rediscovered as a sustainable material in recent years. The hemp plant is an eco-friendly crop that is resistant to pests and does not require herbicides or pesticides. Hemp plastic can be made from both industrial hemp and marijuana plants, but industrial hemp is more commonly used as it has a lower THC content.

Advantages of Hemp Plastic

Hemp plastic has numerous advantages over traditional plastics. Firstly, it is biodegradable and compostable, meaning it does not harm the environment like traditional plastics. Secondly, it is renewable and sustainable as the hemp plant grows quickly and does not require herbicides or pesticides. Thirdly, it is non-toxic and does not release harmful chemicals when heated, making it safer for use in food packaging. Lastly, hemp plastic has excellent mechanical properties and can be molded into a variety of shapes and sizes.

Properties of Hemp Plastic

Hemp plastic has several properties that make it an excellent alternative to traditional plastics. It has a high tensile strength, which means it is strong and durable. It is also lightweight, making it ideal for use in transportation applications. Hemp plastic is resistant to heat, UV light, and chemical corrosion, making it an excellent material for use in harsh environments. Additionally, hemp plastic has a low carbon footprint and does not produce harmful emissions during manufacturing.

Manufacturing Process of Hemp Plastic

The process of making hemp plastic involves taking the fibers from the stalk of the hemp plant and mixing them with a biodegradable plastic resin. The mixture is then molded into the desired shape using heat and pressure. The resulting product is a biodegradable plastic that is eco-friendly and sustainable. The manufacturing process of hemp plastic is less harmful to the environment than traditional plastic manufacturing processes, as it uses less energy and produces fewer emissions.

Applications of Hemp Plastic

Hemp plastic can be used in a variety of applications, including packaging, automotive parts, construction materials, and consumer goods. It is an excellent material for use in food packaging as it is non-toxic and does not release harmful chemicals. Hemp plastic can also be used in the production of car parts as it is lightweight and durable. Additionally, hemp plastic can be used in construction materials, such as insulation and roofing, due to its excellent properties.

Comparison with Traditional Plastics

Hemp plastic has several advantages over traditional plastics. Firstly, it is biodegradable and does not harm the environment. Secondly, it is renewable and sustainable, whereas traditional plastics are made from non-renewable fossil fuels. Thirdly, hemp plastic is non-toxic and does not release harmful chemicals, whereas traditional plastics can release harmful chemicals when heated. Lastly, hemp plastic has excellent mechanical properties and can be molded into a variety of shapes and sizes, making it more versatile than traditional plastics.

Environmental Impact of Hemp Plastic

Hemp plastic has a low environmental impact compared to traditional plastics. The production of hemp plastic requires less energy and produces fewer emissions than traditional plastic manufacturing processes. Additionally, hemp plastic is biodegradable and compostable, meaning it does not harm the environment like traditional plastics. Hemp plastic can also be recycled, reducing the amount of waste that ends up in landfills.

Future of Hemp Plastic

The future of hemp plastic looks bright as more companies are turning to sustainable materials. Hemp plastic has the potential to revolutionize the plastics industry by providing a renewable, biodegradable, and eco-friendly alternative to traditional plastics. As the demand for sustainable products increases, the hemp plastic industry is likely to grow.

Challenges faced by Hemp Plastic Industry

Despite the numerous advantages of hemp plastic, the industry still faces several challenges. Firstly, the cost of producing hemp plastic is still higher than traditional plastics, making it less accessible to consumers. Secondly, the supply of industrial hemp is limited, which can lead to shortages and price fluctuations. Lastly, there is still a lack of awareness about hemp plastic, which can hinder its adoption.

Hemp Plastic Regulations

The regulations surrounding hemp plastic vary from country to country. In the United States, hemp plastic is legal to produce and use, but it must be made from industrial hemp and cannot contain more than 0.3% THC. In Europe, hemp plastic is also legal to produce and use, but it must meet specific standards for biodegradability and compostability.

Conclusion on Hemp Plastic

Hemp plastic is a renewable, biodegradable, and eco-friendly alternative to traditional plastics that has numerous advantages. It has excellent mechanical properties, is non-toxic, and has a low environmental impact. Hemp plastic can be used in a variety of applications, from packaging to construction materials. Although the industry still faces challenges, such as limited supply and high costs, the future of hemp plastic looks promising. As more companies turn to sustainable materials, hemp plastic has the potential to revolutionize the plastics industry and provide a more sustainable future.